Freezer Trailer vs Refrigerated Van: What’s Best For You?

Freezer Trailers and Refrigerated Vans are both essential tools in the transportation industry for maintaining the proper temperature of temperature-sensitive goods during transit. Understanding the differences between these two options is crucial to determine the best choice for your specific shipping needs.

What is a Freezer Trailer?

A small freezer trailer is a type of refrigerated trailer equipped with a refrigeration unit designed to transport goods that require below-freezing storage temperatures. It has insulated walls and a cooling system that maintains the cargo area at extremely low temperatures, making it ideal for transporting frozen foods, dairy products, and other temperature-sensitive items.

What is a Refrigerated Van?

On the other hand, a refrigerated van, also known as a reefer van, is a vehicle with an integrated refrigeration system specifically designed for transporting perishable goods. It offers a temperature-controlled environment to ensure the freshness and quality of the cargo.

Key takeaway:

Freezer trailers and refrigerated vans both offer temperature control for transporting temperature-sensitive goods.

Freezer trailers have higher refrigeration capacity and are more suitable for transporting perishable items that require below zero storage temperatures and more cost effective.

Refrigerated vans are easier to maneuver in tight spots but more expensive to own and maintain especially 70% higher insurance rates and maintenance cost.

Comparing Freezer Trailers and Refrigerated Vans:

Temperature Control:

Freezer trailers are capable of maintaining sub-zero temperatures, making them suitable for transporting goods that require the most significant freezing. Refrigerated vans, while still providing temperature control, may not reach as low temperatures as freezer trailers.

Insulation and Cooling Units:

Freezer trailers often have more advanced insulation and cooling units to handle the extreme temperatures required. Refrigerated vans have insulation as well but may not have the same level of insulation as freezer trailers.

Maximum Weight Capacity:

Freezer trailers typically have a higher refrigeration capacity and are capable of carrying more weight compared to refrigerated vans.

Advantages and Disadvantages of Refrigerated Vans:

Advantages of refrigerated vans include their smaller size, making them more maneuverable and accessible to various locations. They also offer lower fuel consumption compared to freezer trailers.

Disadvantages of refrigerated vans are the limited refrigeration capacity and cargo space, making them less suitable for transporting larger loads or goods that require extremely low temperatures. Higher costs initially and ongoing insurance and maintenance is more expensive.

Understanding Freezer Trailers and Refrigerated Vans

When it comes to understanding freezer trailers and refrigerated vans, it’s crucial to know the differences between these two types of vehicles. These specialized transportation options play a vital role in ensuring the safe delivery of temperature-sensitive goods. Below, we provide all the necessary information you need to acquire a comprehensive understanding of freezer trailers and refrigerated vans.

1. Functionality: Freezer trailers and refrigerated vans are designed specifically for maintaining low temperatures during transportation to safeguard perishable goods.

2. Temperature Control: Both freezer trailers and refrigerated vans are equipped with advanced insulation and cooling units to effectively regulate temperatures, thus minimizing the risk of heat exposure.

3. Insulation: Freezer trailers excel in insulation, surpassing that of refrigerated vans. This advanced insulation enables freezer trailers to sustain sub-zero storage temperatures for considerably longer periods.

4. Capacity: Freezer trailers usually offer higher refrigeration capacity, enabling the transport of large quantities of frozen foods, dairy products, and other items that require a controlled temperature environment.

5. Loading and Unloading: Both freezer trailers and refrigerated vans possess cargo areas that are cooled to facilitate seamless loading and unloading processes.

6. Fuel Efficiency: When comparing fuel efficiency, refrigerated vans are generally more efficient than freezer trailers due to their lower energy requirements for temperature maintenance.

7. Cost Effectiveness: Refrigerated vans are more expensive compared to freezer trailers, especially for transporting perishable goods over shorter distances.

To determine the most suitable trailer type for your shipping needs, it is essential to understand the differences between freezer trailers and refrigerated vans. Factors to consider include temperature requirements, cargo capacity, and cost. By carefully evaluating these aspects, you can make an informed decision that aligns with your specific requirements.

In summary, small freezer trailers can be a great refrigerated truck alternative and are indispensable tools in the transportation industry, ensuring the secure delivery of perishable items. By comprehending their functionality and capabilities, you can confidently select the trailer type that best suits your needs.

Comparing Small Refrigerated Trailers and Refrigerated Vans

Insulation and Cooling Units

Insulation and cooling units are indispensable components of freezer trailers and refrigerated vans that guarantee optimum temperature control for transporting goods that are sensitive to temperature changes.

The insulation in these vehicles plays a pivotal role in maintaining the desired temperature within the cargo area. It effectively prevents the intrusion of external heat or cold and aids in preserving the cool air generated by the cooling units.

The insulation used in these vehicles is typically crafted from advanced materials that deliver exceptional thermal efficiency. For instance, certain trailers and vans are equipped with more sophisticated insulation options, such as foam panels or vacuum-insulated panels, which offer superior insulation properties when compared to conventional materials.

The cooling units are responsible for regulating and sustaining the temperature inside the cargo area. These units employ refrigeration systems to extract heat from the cargo space and maintain it at the specified temperature.

They are designed to operate with high efficiency and reliability, ensuring consistent cooling performance throughout transportation. Some cooling units even come with defrost heaters to prevent the accumulation of ice on the evaporator coils, thereby ensuring optimal cooling efficiency.

Maximum Weight Capacity

The maximum weight capacity is an important consideration when choosing between a freezer trailer and a refrigerated van for transporting temperature-sensitive goods. The weight capacity determines the amount of cargo that can be safely transported and is influenced by factors such as the size and design of the vehicle.

Considerations for Transporting Temperature-Sensitive Goods

When it comes to transporting temperature-sensitive goods, there are certain considerations that must be taken into account. Understanding the types of goods that require temperature control and the importance of maintaining that control is crucial for a successful and efficient transport process.

From perishable food items to medical supplies, the need for a temperature-controlled environment cannot be underestimated. Join us as we explore the ins and outs of transporting these delicate goods and discover why temperature control is of utmost importance in ensuring their quality and integrity throughout the journey.

Importance of Maintaining Temperature Control

To ensure safety and quality, the importance of maintaining temperature control is of utmost importance when transporting temperature-sensitive goods.

The proper storage and transportation of perishable items, such as frozen foods, dairy products, and medical supplies, depends on consistent temperature control to prevent spoilage and maintain product integrity.

Choosing the Right Trailer Type for Your Shipping Needs

Evaluation of Shipping Requirements

To properly evaluate shipping requirements, it is essential to consider various factors. One key aspect is the size and weight of the cargo, as this will determine the capacity needed in a trailer. It is important to accurately calculate the maximum weight capacity of the trailer to ensure the safe transportation of goods.

Another factor to evaluate is the specific requirements of the shipment. For temperature-sensitive goods, such as perishable items or medical supplies, a trailer with temperature control functionality is crucial.

The type of goods being transported should be taken into account. Some products may require below-zero storage temperatures, while others may have specific climate control needs. Understanding the specific temperature requirements is essential to select the appropriate trailer.

The distance and duration of the transportation should be considered when evaluating shipping requirements. For long-distance trips, it is crucial to ensure the trailer has advanced insulation and cooling units to maintain temperature control throughout the journey.

Cost-Effectiveness

When it comes to choosing the right trailer type for your shipping needs, cost-effectiveness plays a pivotal role. Here are some important factors to consider:

Initial Investment: Cost-effectiveness is a crucial aspect to contemplate while comparing freezer trailers and refrigerated vans. Small freezer trailers have a lower upfront cost compared to refrigerated vans. The purchase and maintenance expenses associated with a refrigerated van can be significant, same as refrigerated trucks.

Fuel Efficiency: Fuel efficiency is an essential consideration when evaluating the cost-effectiveness of trailer types. Refrigerated vans can be more fuel-efficient than small freezer trailers. This can result in long-term savings, particularly if you frequently embark on long-distance trips.

Operating Costs: When assessing cost-effectiveness, it is important to consider the operating costs. Small freezer trailers have a separate refrigeration unit to maintain the desired temperature. These units consume energy and require regular maintenance, contributing to the overall operating costs but the reefer unit on a van or reefer trucks will require a more expensive specialist to maintain.

Flexibility: It’s worth noting that refrigerated vans offer greater flexibility in terms of maneuverability and accessibility. They can be easily loaded and unloaded at various locations, including tight spaces or areas without a loading dock but a small freezer trailer can be dropped at a customers location without needing an extra driver and rental income opportunities are greater.

Capacity: The cargo capacity of a trailer is an important factor to consider for cost-effectiveness. Freezer trailers generally have a larger cargo capacity compared to refrigerated vans. This can be advantageous if you have a substantial volume of temperature-sensitive goods to transport.

Resale Value: The resale value of a trailer is another aspect to think about in terms of cost-effectiveness. New refrigerated vans typically lose their resale value compared to freezer trailers. This can be beneficial if you have plans to upgrade or sell your vehicle in the future.

Flexibility and Versatility

When it comes to flexibility and versatility, both freezer trailers and refrigerated vans have their advantages. Here are some key points to consider:

Multi-purpose use: A small reefer trailer and refrigerated vans can be used for various purposes, such as transporting perishable goods, frozen foods, and temperature-sensitive goods. They are ideal for industries such as the transportation industry, food industry, and medical supplies.

Temperature control: Both small freezer trailers and refrigerated vans offer temperature-controlled environments to ensure that goods remain at the desired temperature. This is crucial for maintaining the quality and safety of the transported goods.

Flexibility in loading and unloading: Both freezer trailers and refrigerated vans provide convenient loading and unloading processes. They typically have cargo areas with easy access and can accommodate different sizes and types of goods.

Adaptability to different environments: Freezer trailers and refrigerated vans are designed to withstand various environmental conditions. They have advanced insulation and cooling units that help maintain low temperatures even in high ambient temperatures.

Flexibility in transportation: Freezer trailers and refrigerated vans can be attached to trucks or used as standalone units, providing flexibility in transportation options. They can be used for local deliveries or long-haul transportation.

Some Facts About Freezer Trailer vs Refrigerated Van:

✅ Freezer trailers and refrigerated vans are both used for transporting temperature-sensitive goods.

✅ Freezer trailers are equipped with insulation and refrigeration systems, while refrigerated vans have cooling units installed.

✅ Freezer trailers can achieve below zero storage temperatures, making them suitable for transporting frozen foods and perishable items.

✅ Refrigerated vans are commonly used in the transportation industry to deliver perishable products like dairy items and medical supplies.

✅ The maximum weight capacity of small freezer trailers and refrigerated vans depends on their design and size, but it typically ranges between 5,000 and 8,000 pounds.

Frequently Asked Questions

What is the difference between a small freezer trailer and a refrigerated van?

A freezer trailer is a type of trailer specifically designed for transporting goods at below zero storage temperatures, while a refrigerated van is a van equipped with a refrigeration system to maintain specific temperature conditions for perishable goods.

What types of items can be transported in a dry van trailer?

Dry van trailers are commonly used to transport dry, non-perishable items such as clothing, furniture, and non-perishable food.

Which type of trailer is suitable for transporting temperature-sensitive goods?

A refrigerated van, also known as a reefer trailer, is the best option for transporting perishable and temperature-sensitive goods like fresh produce and medications.

What is the weight capacity of a dry van trailer?

Dry van trailers typically have a weight capacity range of 42,000-45,000 pounds, allowing for the transportation of various types of cargo.

Can a dry van trailer be used to transport frozen foods?

No, dry van trailers are not suitable for transporting frozen foods or goods that require below zero storage temperatures. A freezer trailer or refrigerated van with a freezing capacity would be the appropriate choice.

Do refrigerated vans and reefer trailers have the same dimensions as dry van trailers?

Yes, refrigerated vans and reefer trailers have the same dimensions as dry van trailers, typically ranging from 48 to 53 feet in length.

The Cooler Trailers Difference

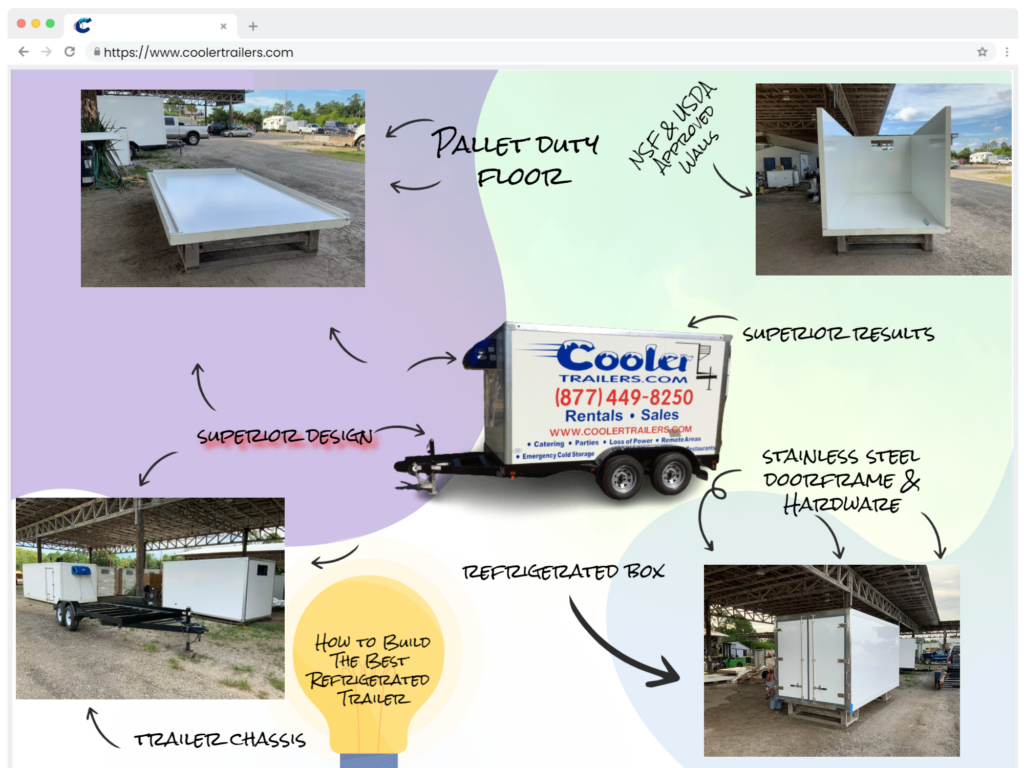

Superior Design For Superior Results

Our Secret:

We build insulated truck bodies and put them on a bumper pull trailer chassis and complete it with 115 volt refrigeration that will freeze or cool.

Starting with an aluminum pallet duty floor then add NSF and U.S.D.A. approved walls ceiling and floors that will pass any inspectors wish list.

Then the most important piece of the refrigerated box, the 304 stainless steel doorframe with EPDM door seals to keep the cold air inside.

Why reinvent the wheel, truck bodies have been serving the industry since the early 1900’s.

We just put them on a bumper pull trailer chassis instead of a refrigerated truck and you save 70% on insurance cost, save thousands on initial cost and keep your maintenance cost to a minimum unlike Thermo-King and Carrier units.

Are you ready to take your business to the next level and crush your competition!

Call us today at 877-449-8250 for pricing and availability.